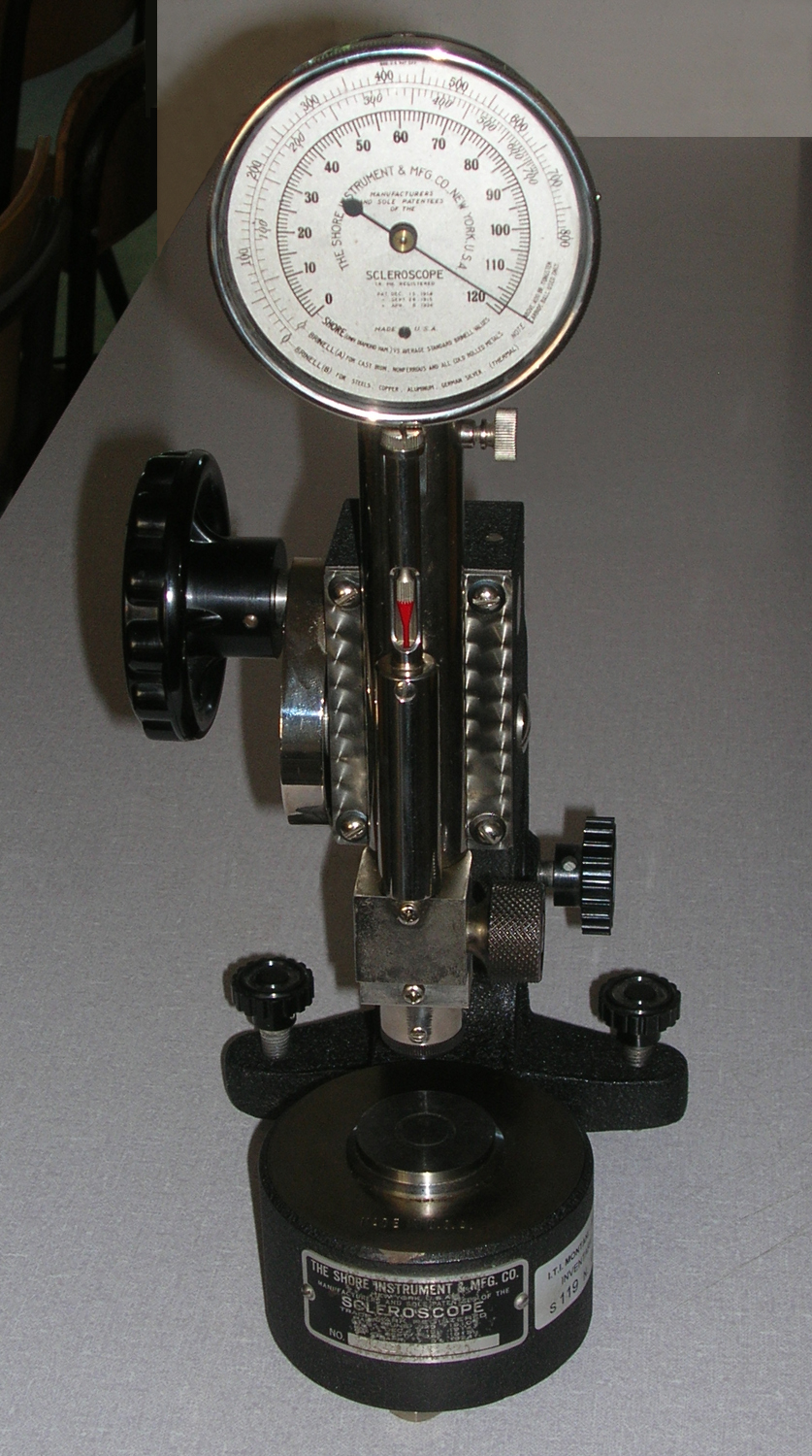

Shore Standard Dial Recording Scleroscope Model D-1 [Seconda parte] (Improved Portable) .

Shore Standard Dial Recording Scleroscope Model D-1 [Seconda parte] (Improved Portable) .

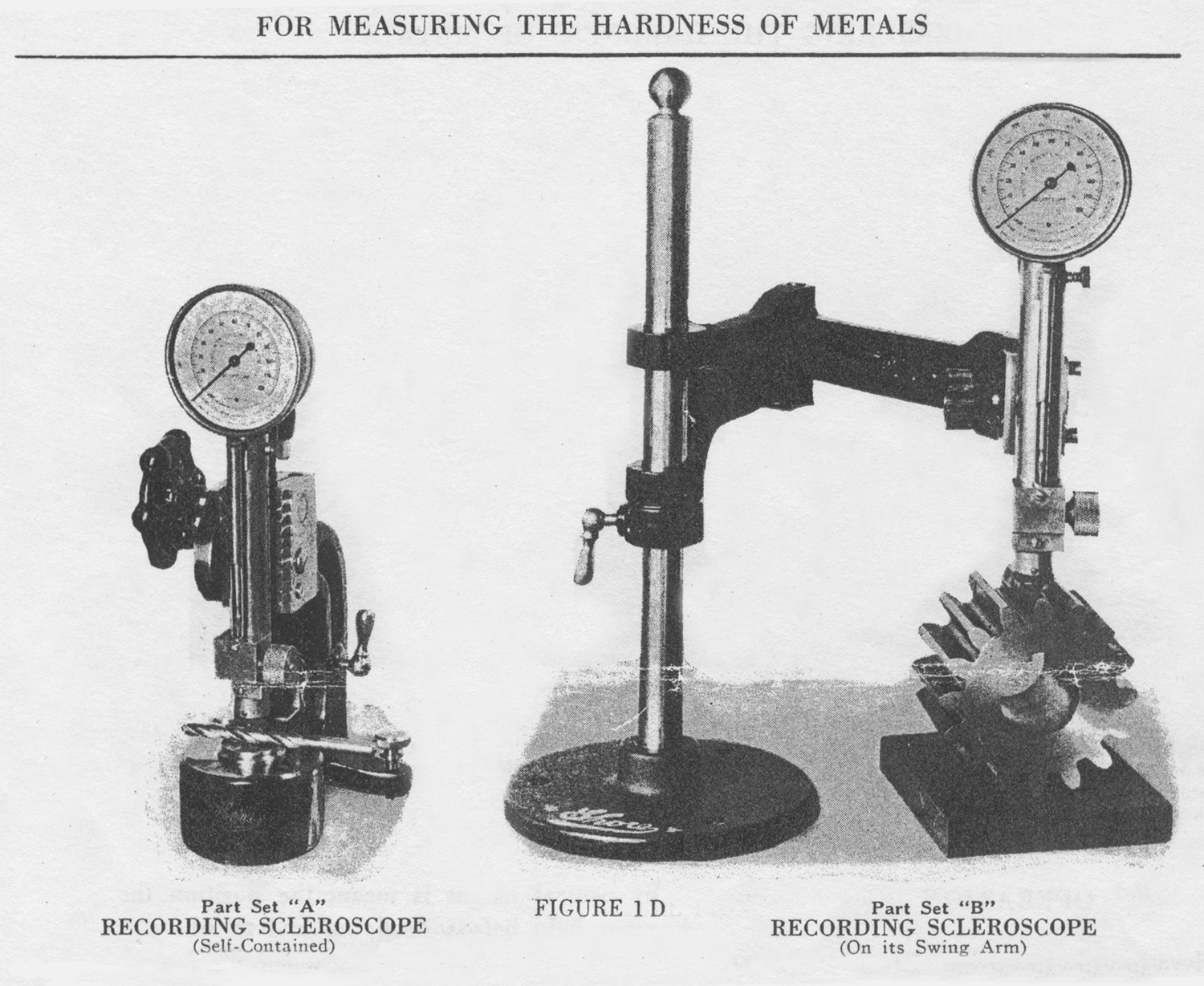

For Measuring The Hardness Of Metals With Equivalent Standard Brinell Graduations.

Le seguenti note sono tratte dal Bulletin S-32 senza data ma di poco posteriore all`agosto 1932.

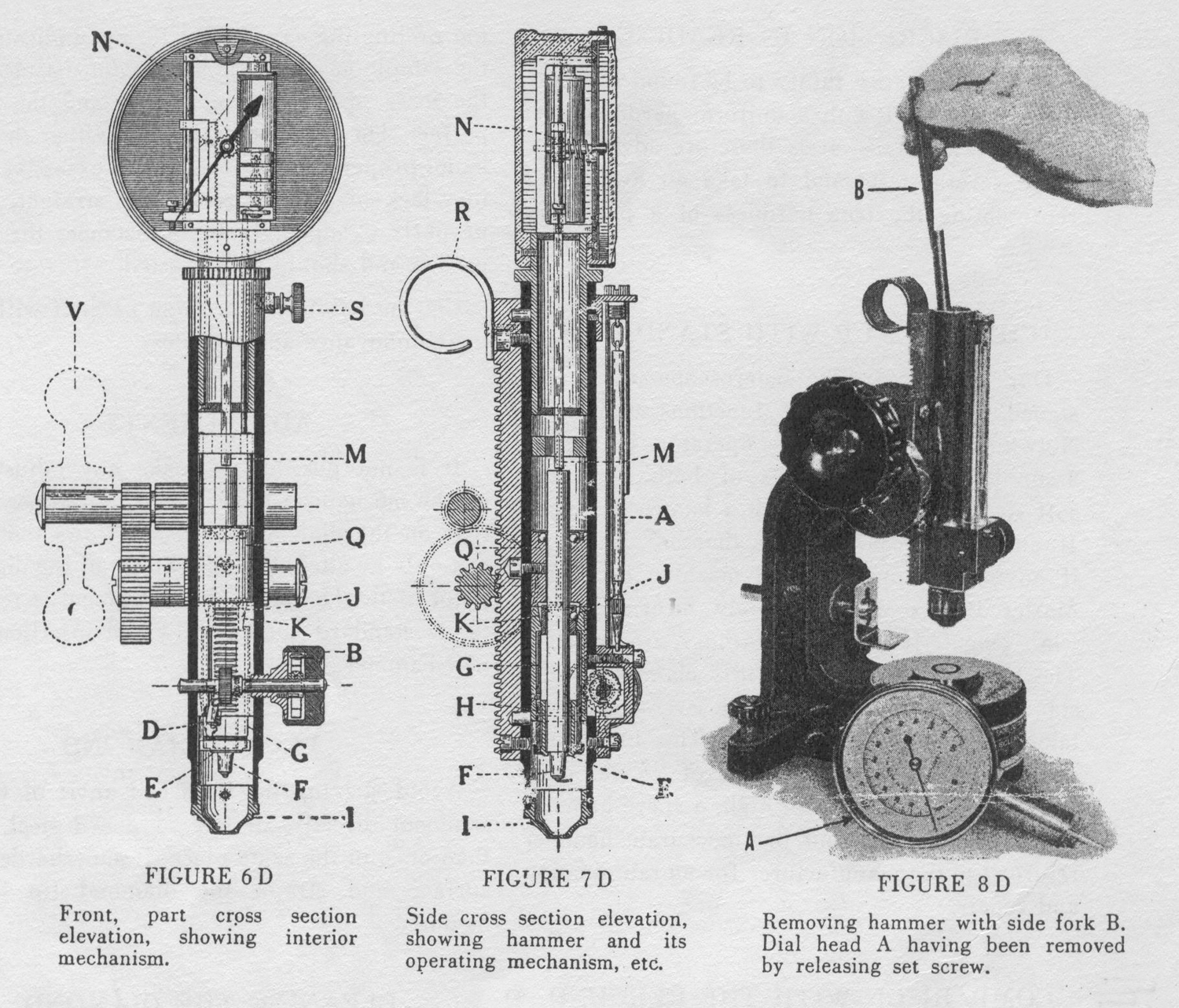

«OPERATION. To elevate, release and drop the hammer, revolve the knurled knob B in a direction clockwise for about five-eights of a turn or until an internal stop is reached. At this point the rebound also occurs which is instantly fixed to its full height by its ball clutch J, Figure 7D. When the knob B is returned to its starting point, the clutch mechanism, togheter with its now somewhat elevated hammer, due to the locked rebound, is raised up and brought in contact with the rack bar M, wich then acts on the dial hand pinion N, turning it to the extended that the aforesaid rebound has raised it above its neutral height. By neutral height is meant the position the hammer held before dropping and to where it returns if there had been a drop but no rebound. In each instance, the top of the hammer contacts with the dial rack bar M, but since it does not impart motion to it, no perceptible movement of the indicator hand occurs.

DIAL HAND REMAINS FIXED. It will be noted that when the knob B is returned, after causing the hammer to strike and to rebound, wich is thus recorded by the dial hand, said hand remains fixed indefinitely or until the knob is again turned for another test. During this turn the indicator hand always return to zero, but it is not adapted to remain there. Its resting place is always at the number of the last hardness test».

Le istruzioni proseguono per otto pagine nelle quali si descrivono: la taratura, le operazioni da farsi in casi particolari, la pulizia dei congegni interni, e infine il confronto con il modello precedente descritto brevemente nella relativa scheda. Ne riportiamo alcune parti. «DISCRETION IN READING. – One of the rarest things to be found in metallurgy is a metal with a uniform hardness over its general surface. It is therefore advisable to make several tests and to take an average as representing the true hardness of a particular sample.

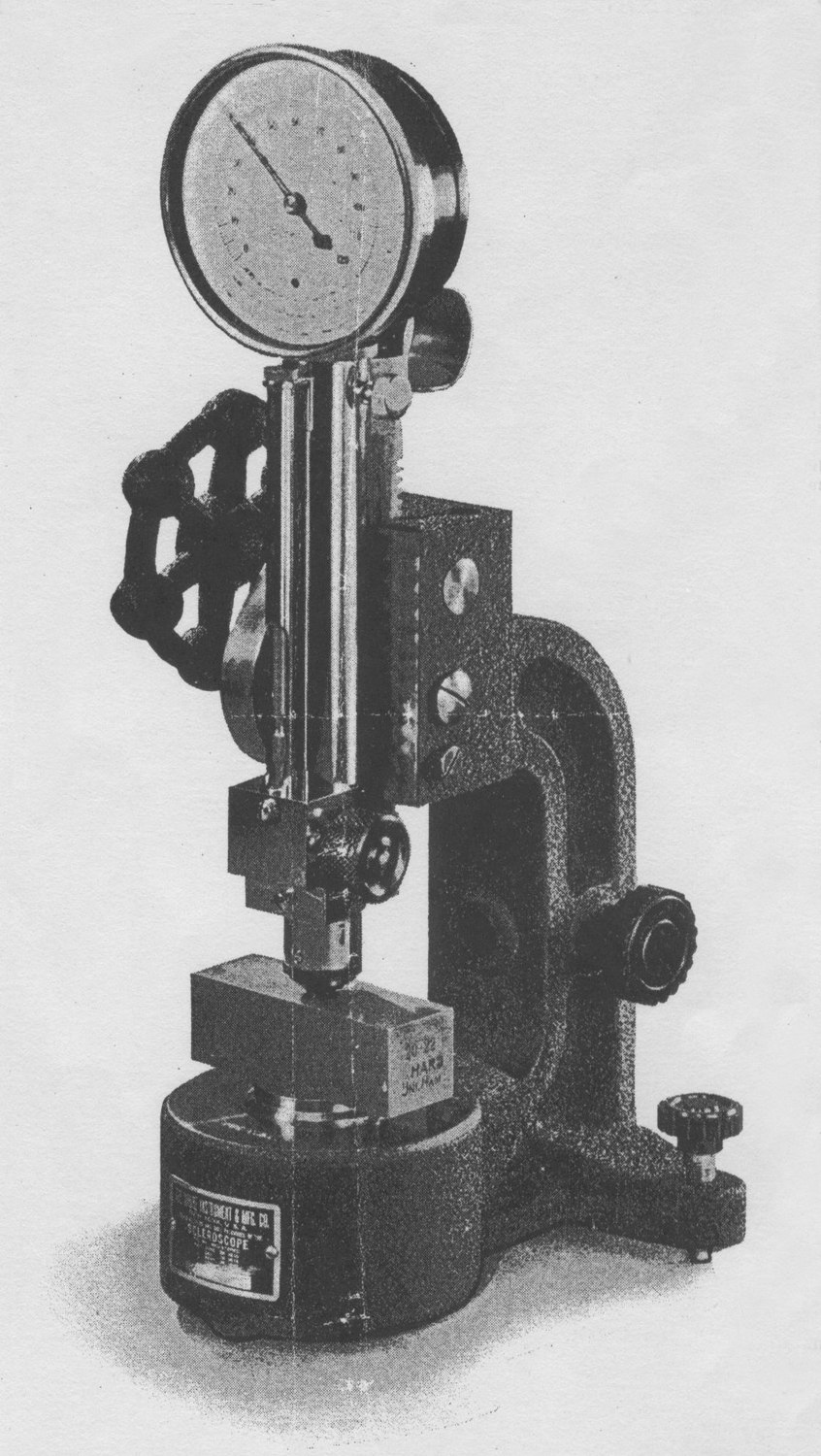

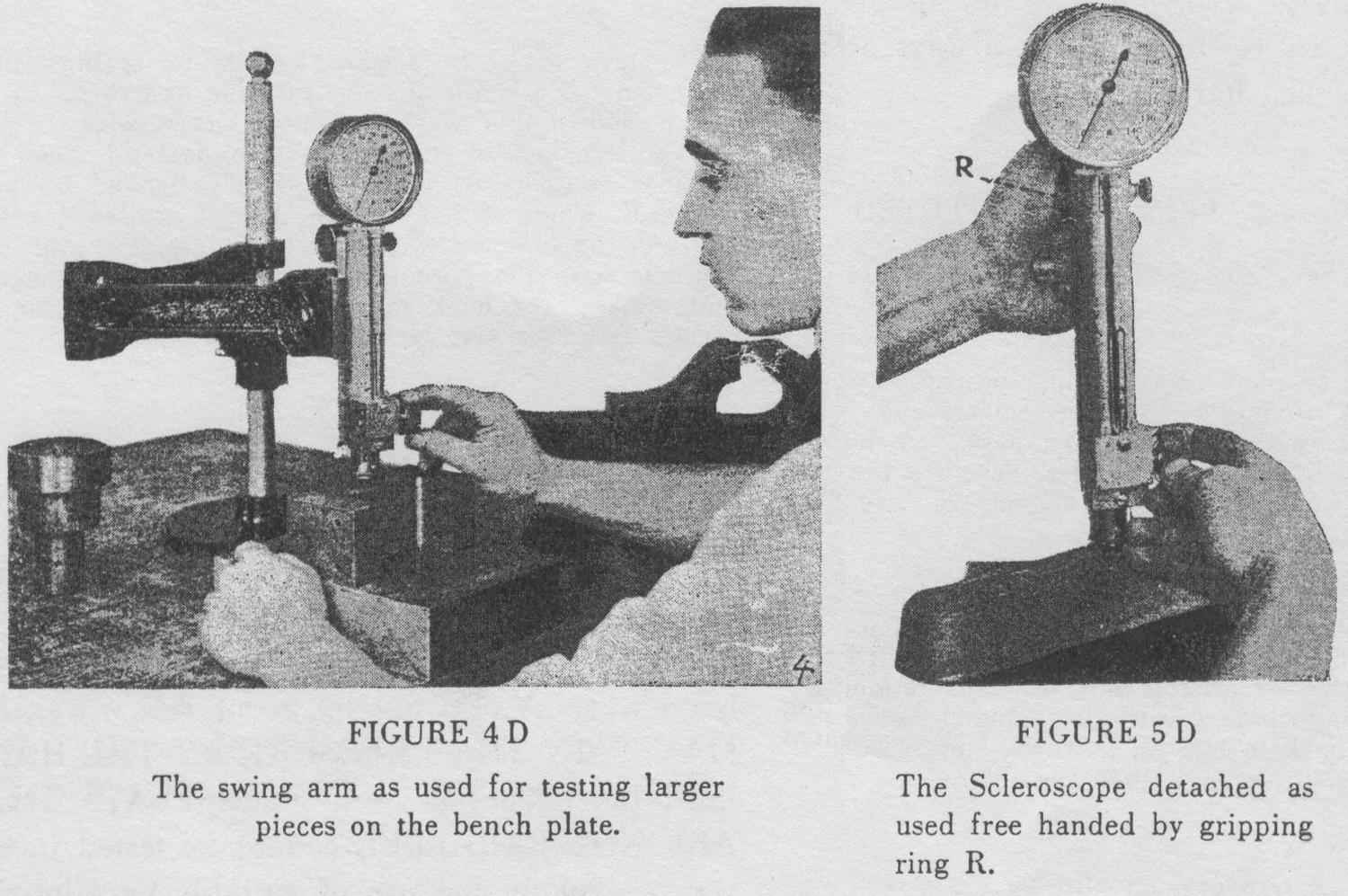

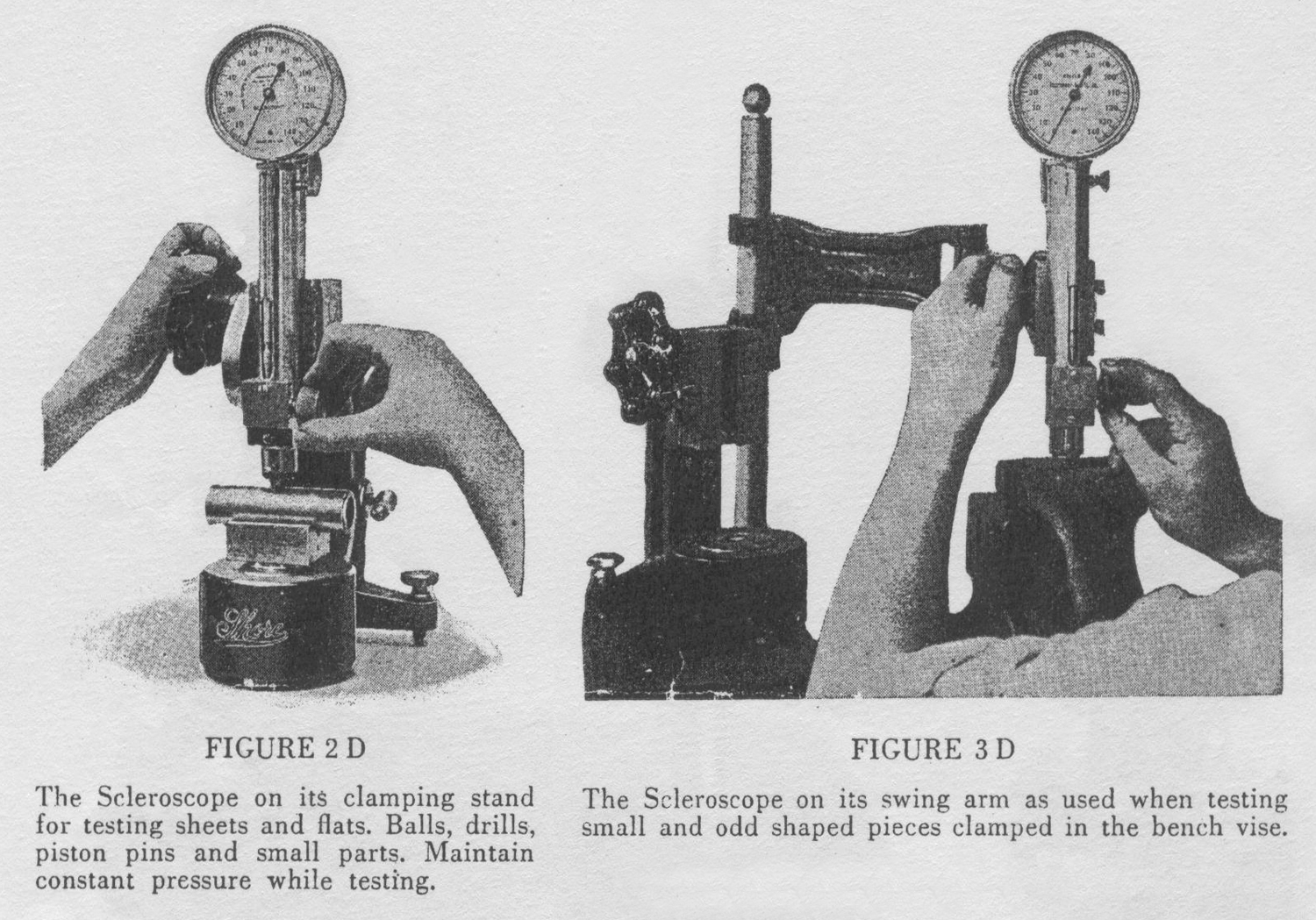

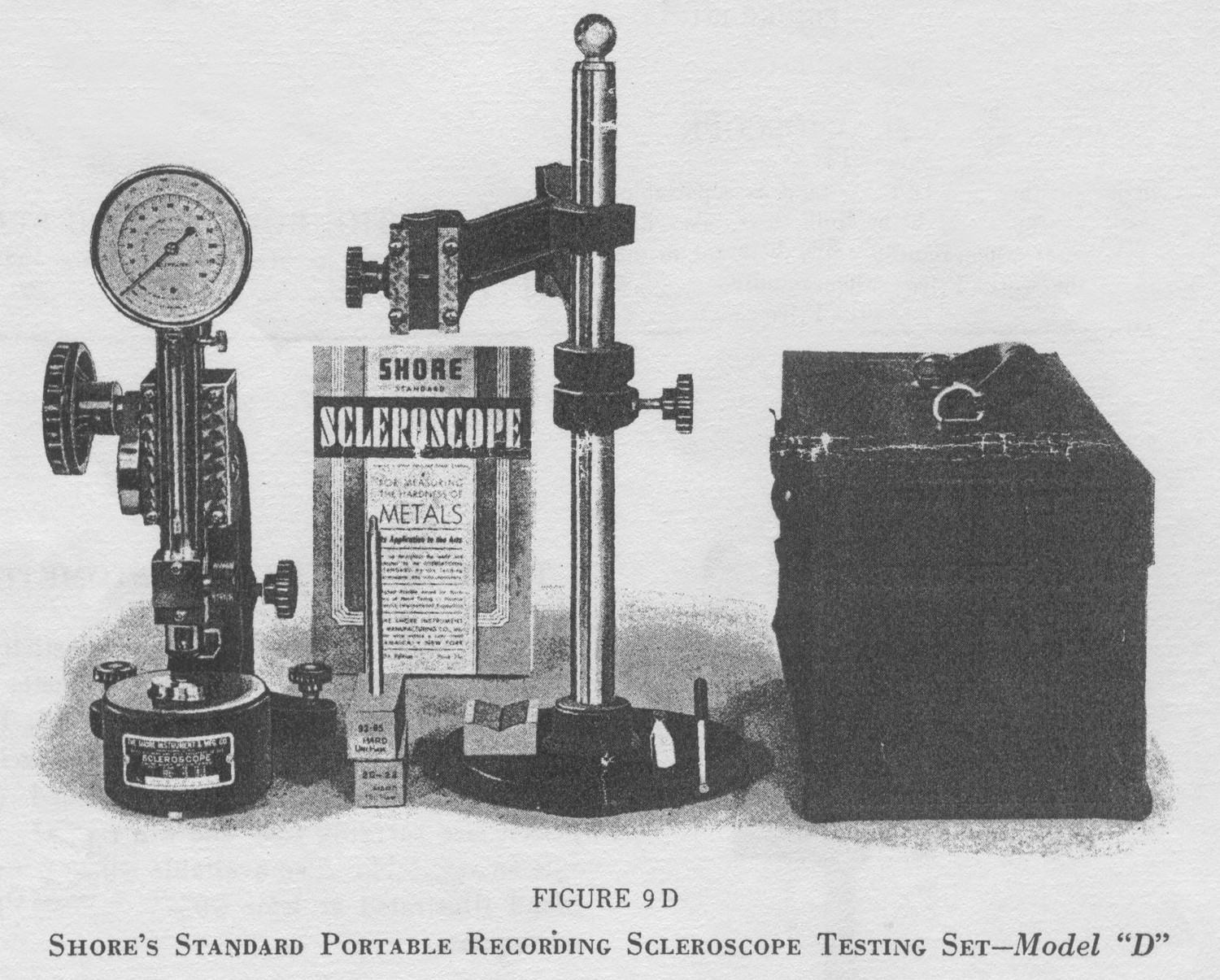

CHECKING UP WITH STANDARDS. Our dial recording Scleroscope is so designed and built that it functions uniformly. Notwithstanding this, the operator is doubly assured by Master Bolcks of both hard and soft steel, each marked with a known hardness. If any wear occurs on the diamond point, or if anything happens to the machine itself, the Master Blocks will accurately inform you to what extent, if any, the readings are affected. The blocks should be carefully clamped in the stand, as per Figure 2 D, and several readings taken to obtain the average.The instruments should then show an accuracy of 95 per cent. If it reads too low or too high, a spare hammer should be inserted and the inaccurate hammer returned to the manufacturer for an examination and repair. ADJUSTMENT. It is not possible to make any adjustments on the mechanism to regulate the hardness readings on the dial, and it also follows that these can only be altered by the failure of the diamond point of the hammer. The instrument is restored to its standard condition by the insertion of a new hammer.

SAVE THE DIAMOND. Avoid striking the hardened anvil of the instrument directly, or any hardned steel, more than once in the same place. It superhardens the surface and strains the diamond tip in the hammer.

CLEANING THE DIAMOND. In the course of testing, dust or scum often accumulates on the diamond tip, wich may slightly affect the accuracy of the readings. Clean same by rubbing or dropping a few times, as in testing metals, on a piece of rubber eraser.

CLEANING INTERIOR SLEEVES. The cleaning brush shown at the right of Fig. 9 is intended for this purpose. It is inserted in place of the hammer and gently moved up and dawn a few times. This should be done every now and then as matter of precaution. Re-insert the hammer with the same fork ».

Bibliografia: Bulletin S-32 edito dalla ditta costruttrice.

Foto di Claudio Profumieri, consulenza del prof. Egisto Mariani che ringraziamo, elaborazioni, ricerche e testo a cura di Fabio Panfili.

Per ingrandire le immagini cliccare su di esse col tasto destro del mouse e scegliere tra le opzioni.

Istituto Tecnico Tecnologico Montani